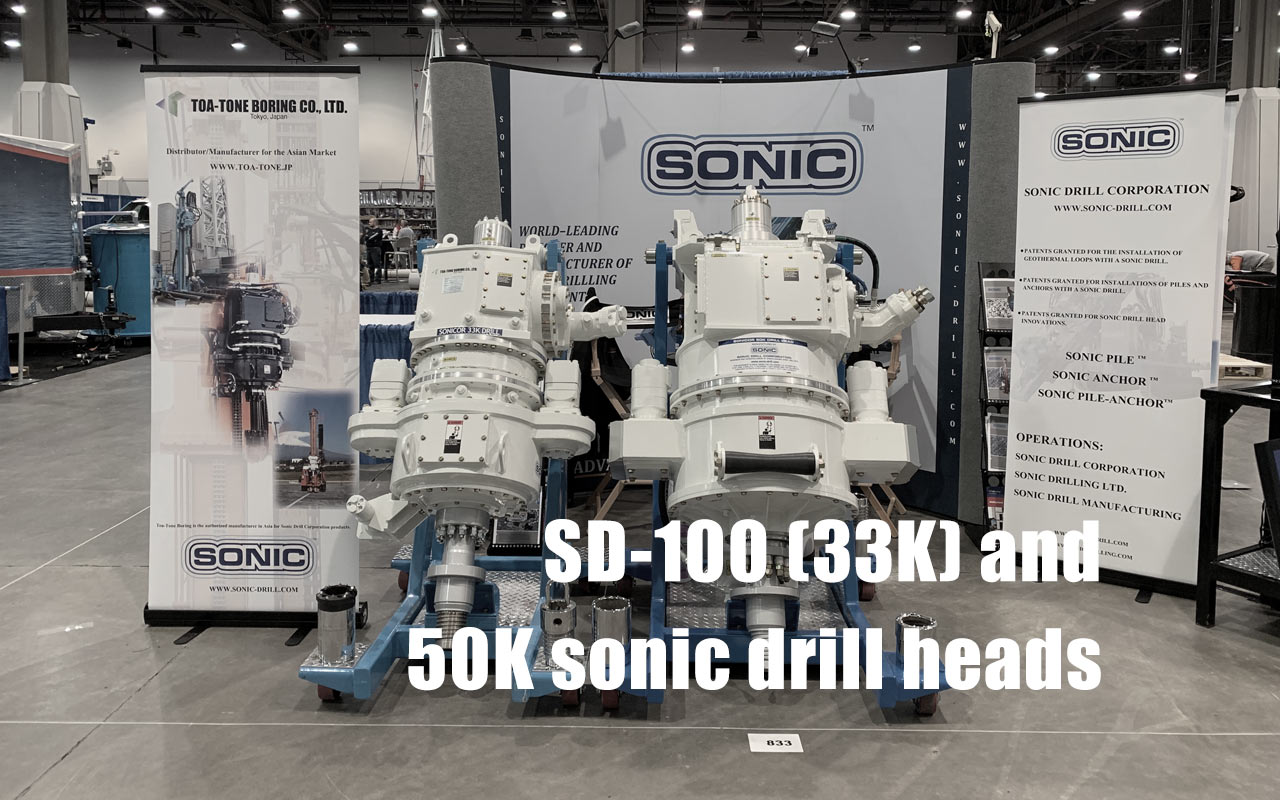

In 2002, Toa-Tone Boring Co., Ltd.,

manufacturer of the TONE-SONIC,

entered into a license agreement with the Sonic Drill Corporation

in Canada to allow us to begin manufacturing

sonic drills using their patented technology.

manufacturer of the TONE-SONIC,

entered into a license agreement with the Sonic Drill Corporation

in Canada to allow us to begin manufacturing

sonic drills using their patented technology.

Sonic Drill Corporation (SDC) and Sonic Drilling Limited's

President, Ray Roussy is well-known as the patent holder and

developer of the modern day sonic drilling technology in

the drilling industry. SDC has delivered many 50K Sonicor

drill heads around the world and it has been highly

evaluated internationally for the performance.

President, Ray Roussy is well-known as the patent holder and

developer of the modern day sonic drilling technology in

the drilling industry. SDC has delivered many 50K Sonicor

drill heads around the world and it has been highly

evaluated internationally for the performance.

Toa-Tone Boring Co., Ltd.

has been a drilling equipment manufacturer

in Japan since 1917, producing rotary drills, mud pumps,

diaphragm wall trenchers and many other products.

As an authorized licensee of the Sonic Drill Corporation's

sonic technology,our main product line

now is shifting to world-class sonic drills.

has been a drilling equipment manufacturer

in Japan since 1917, producing rotary drills, mud pumps,

diaphragm wall trenchers and many other products.

As an authorized licensee of the Sonic Drill Corporation's

sonic technology,our main product line

now is shifting to world-class sonic drills.

We have also invented and manufactured the TONE-PROBE drill rig which is more compact than the TONE-SONIC drill. The TONE-PROBE series are mostly used for shallow samplings including environmental investigations.

Genuine Sonic Drill Head with

Air Damper

The air damper of our sonic drills can properly handle the high frequency and powerful vibrational force produced by sonic technology by transmitting this force to the sonic bit only.

The success of this power transmittance by our air damper produces great drilling performance such as a fast penetration rate, excellent sample quality, flexibility when drilling in a variety of ground formations and versatility for many drilling applications.

The success of this power transmittance by our air damper produces great drilling performance such as a fast penetration rate, excellent sample quality, flexibility when drilling in a variety of ground formations and versatility for many drilling applications.

More information on

”BENEFIT” page

”BENEFIT” page

Overview of

Sonic Drilling Technology

Offering unparalleled performance in overburden soil conditions, award-winning patented sonic drilling technology can drill three to five times faster – all without the use of drilling mud and with 70-80% less waste. Sonic drills can also provide continuous undisturbed core samples to a depth of 100 meters – a significant advantage over all other drills. Plus, geothermal projects are simplified with the sonic drill’s patented one-step drill, case, loop and grout system.

Due to its non-intrusive abilities, sonic drilling technology has also been used for sensitive projects such as dam remediation, nuclear site investigations and hazardous waste site reclamation. Because vibrations from the drill bit are not transmitted very far beyond the drill, penetrations can occur into very sensitive areas such as critical eco-systems, unstable terrain or vulnerable situations where traditional drilling would cause more harm or be impossible to complete.

Due to its non-intrusive abilities, sonic drilling technology has also been used for sensitive projects such as dam remediation, nuclear site investigations and hazardous waste site reclamation. Because vibrations from the drill bit are not transmitted very far beyond the drill, penetrations can occur into very sensitive areas such as critical eco-systems, unstable terrain or vulnerable situations where traditional drilling would cause more harm or be impossible to complete.